HF -3000 and laser cladding

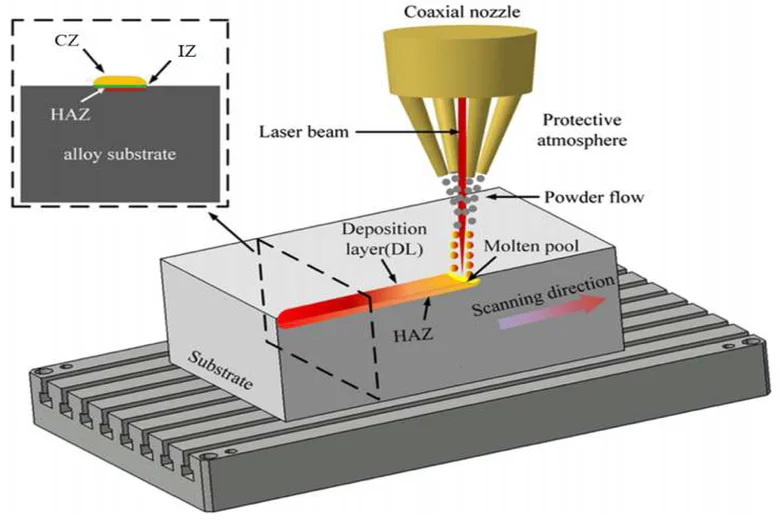

HF-3000 is a high-frequency induction heating system used in various industries for processes like hardening, brazing, and heat treatment. It provides precise control over temperature and heating zones, ensuring uniform and efficient heating of metal parts. Laser cladding, on the other hand, is an advanced surface modification technique that uses a high-powered laser to melt and deposit a layer of material (usually metal powder) onto a substrate, creating a strong, wear-resistant surface.

Category: Accessories

Related products

bearing housings

Bearing housings are protective enclosures that house and support bearings, ensuring proper alignment and stability during operation. Made from materials such as cast iron, steel, or aluminum, bearing housings provide a secure mounting for bearings, preventing dirt, moisture, and debris from contaminating the bearing while also minimizing the risk of damage.

CAF gaskets and flexi couplings

CAF (Compressed Asbestos Fiber) gaskets and flexi couplings are essential components used to enhance sealing and flexibility in mechanical systems. CAF gaskets are made from a blend of asbestos fibers and other materials, providing excellent resistance to heat, pressure, and chemical exposure. They are commonly used in applications like engines, pipelines, and pumps. However, due to health concerns surrounding asbestos, alternative materials are often being used today.

cross overs

Crossovers are devices or components used in various fields, most commonly in audio systems and mechanical applications. In audio, a crossover is an electronic filter that divides an audio signal into different frequency ranges, ensuring that each speaker or driver receives the appropriate signals (e.g., bass, midrange, or treble) for optimal sound quality.

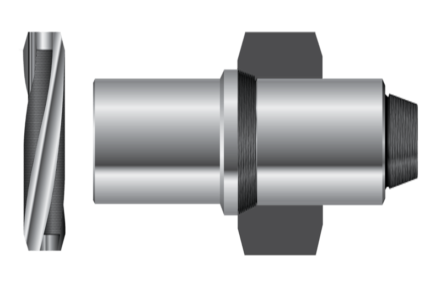

Manufacturing of down hole tool

The manufacturing of downhole tools involves the design and production of specialized equipment used in the oil and gas industry to perform operations in wells beneath the Earth's surface. These tools, such as drill bits, casing, tubing, and pressure gauges, are engineered to withstand extreme temperatures, pressures, and harsh environments.

motor stabiliser sleeves

Motor stabilizer sleeves are protective components used in electric motors to provide stability and support during operation. These sleeves are typically made from durable materials like steel or composite alloys and are designed to fit around the motor shaft or housing, reducing vibrations and ensuring smooth, consistent performance.

Special castings and supply of alloy steel including duplex and Monel etc

Special castings and the supply of alloy steels, including materials like duplex stainless steel and Monel, are essential for industries requiring high-performance and corrosion-resistant components. Special castings involve the creation of complex metal parts through precision casting processes, often using alloys that offer superior strength, durability, and resistance to extreme conditions.

specialised welding and fabrication including string magnet

Specialized welding and fabrication involve advanced techniques and processes tailored to meet the unique requirements of complex or high-performance projects. This includes welding methods such as TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and laser welding, which are used for precision work on materials like steel, aluminum, and exotic alloys.

Reviews

There are no reviews yet.